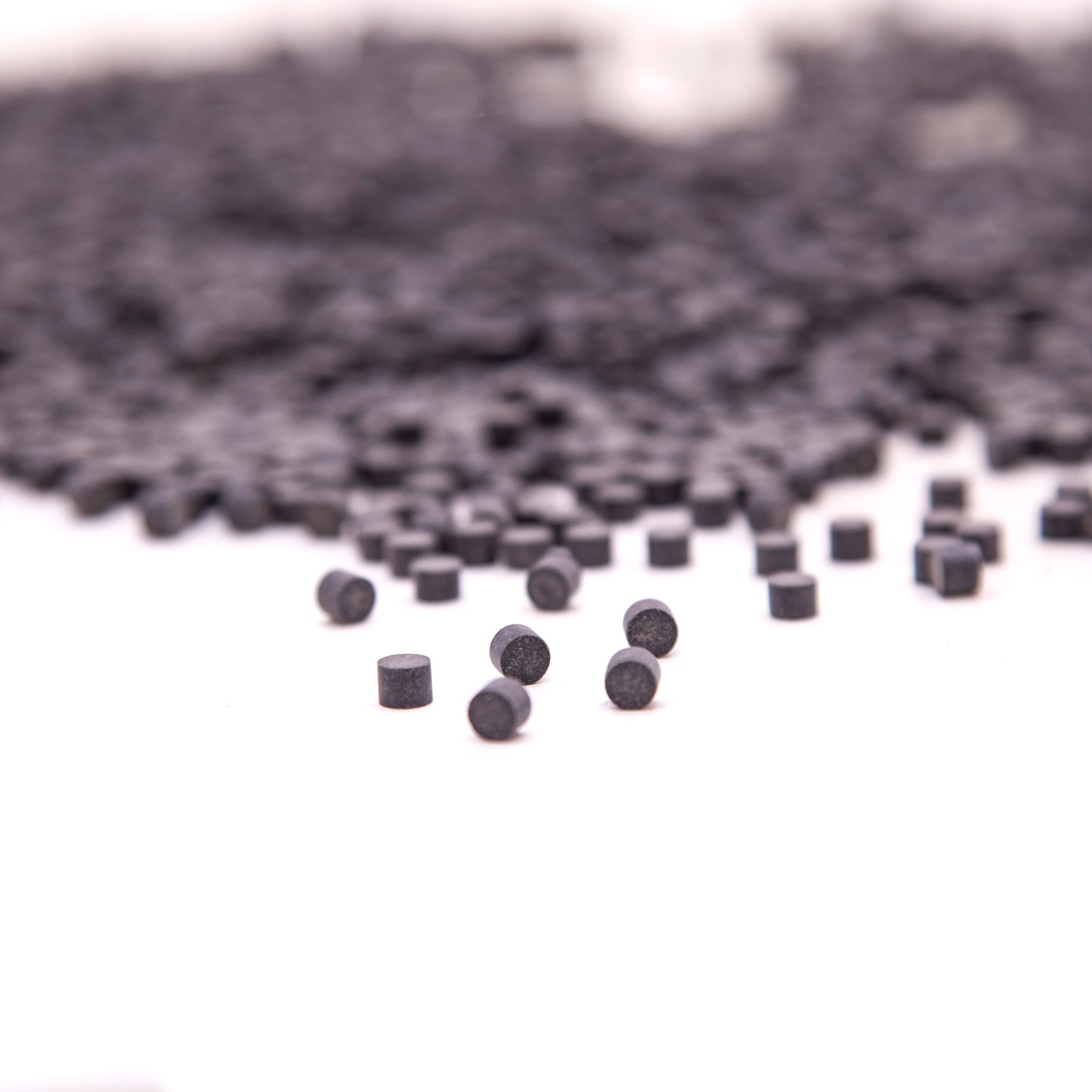

Methanation Catalyst – SARV160

Methanation catalyst is based on nickel oxide supported by various refractory oxides such as alumina, silica. Nickel oxide must be reduced to nickel metal in the plant reactor before use. Successful catalysts must therefore be easily reduced, have high stable activity, and retain high strength for long periods. This is achieved with SARV-160 catalysts by forming NiO to provide a structure in which crystallite growth (sintering) of nickel oxide during manufacture, or nickel metal during operation, is negligible. The only significant form of deactivation during operation is poisoning.

High strength in SARV-160 catalyst is provided by NiO and alumina which set after forming the pellets. As a result, no strength is lost during the nickel oxide reduction, and the pellets neither shrink nor break up during use.

SARV methanation catalyst has been formulated to give high and stable activity. This has been demonstrated by pilot scale experiments in our research laboratories. Catalysts are operated under severe test conditions in order to illustrate differences in activity.

Process:

Methanation catalyst is a nickel-based catalyst, which has high activity for methanation reaction. Most modern ammonia and conventional hydrogen plants use the methanation reaction to remove traces of carbon oxides from the process gas. This involves the conversion of carbon oxides to methane and water by the use of a nickel-based catalyst.

Relatively low levels of carbon oxides limit the temperature rise during reaction and extend catalyst life. Now that even better catalysts are available, low-temperature carbon monoxide conversion followed by removal of carbon dioxide and methanation is the most commonly used process gas purification procedure. A simple adiabatic reactor is used downstream of the conventional carbon dioxide removal step. Most methanators tend to run at an inlet temperature between 200 and 330 ºC (500–610 ºF) with space velocities around 1000–9000 hr⁻¹. SARV-160 catalyst is formulated to perform over a range of conditions and with considerable performance and long life.

Category:

Date:

May 31, 2025