The History

of SARV Oil & Gas

It Started with an Idea

The story of SARV is the journey of a small startup founded in 2004 that grew to become the market leader in Iran. This tale began with an idea born from the needs of the Iranian market...

2004

Establishment of SARV Company

SARV Oil & Gas Industries Development Company officially began its operations with the goal of acquiring advanced technologies in the GTL field and industrial production of catalysts.

- Official launch of SARV Oil & Gas Industries Development Company

- Setting the goal for localizing GTL technology and developing technical knowledge for advanced catalyst production

2005

Initiation of Catalyst Technology Industrialization

- Start of the industrialization phase for steam reforming catalyst production

2006

Entering the Steel Industry Catalysts Sector

Start of the industrialization phase for producing Direct Reduction Iron (DRI) catalysts

2007

Technical Know-how Development and Start of Field Tests

- Patent registration of in-house catalyst technologies

- Start of semi-industrial loading of DRI catalysts at Khouzestan Steel Company

2008

Start of Industrial Operation of Localized Catalysts

First-ever industrial loading of domestically-produced methane reforming catalyst at Shiraz Petrochemical Complex

2009

Consolidating the Company's Innovative Position at the National Level

- Selection of the GTL project as a top project at the Khwarizmi Festival

- Start of semi-industrial loading of DRI catalysts at Mobarakeh Steel

2010

Start of Mass Production of Nickel Catalysts

Official inauguration of the industrial production line for nickel catalysts

2011

A Major Step in Commercializing GTL Technology

Inauguration and operation of the first semi-industrial GTL unit with a production capacity of one barrel per day

2012

Expanding the Catalyst Product Portfolio

- Start of production of enhanced steam reforming catalysts

- Receiving the "Top Product of the Year" award, jointly with Khouzestan Steel

2013

Operational Entry into Petrochemical and Steel Industries

- First industrial loading of DRI catalyst in Mobarakeh Steel's Module B

- Loading of reforming catalysts at Fanavaran, Razi, and Shiraz Methanol Petrochemical plants

- Obtaining approval from the Research Institute of Petroleum Industry (RIPI) for the industrial production line of reforming catalysts

2014

Consolidating Knowledge-Based Position and Initiating Specialized Interactions

- Recognition as a knowledge-based manufacturing company by the Vice-Presidency for Science and Technology

- Loading of steam reforming catalyst at Pardis Petrochemical Complex

- Organizing the First National Conference on Catalyst Localization and Direct Reduction Iron Process

2015

Market Share Growth and Production Records

- First-ever loading of secondary reforming catalyst in the country at Razi Petrochemical

- Achieving a production record of one million liters of various catalysts

- Loading of DRI catalysts at Khouzestan Steel's Unit 3, Mobarakeh Steel's Module A, and Hormozgan Steel

- Loading of methane reforming catalyst at Arak and Shiraz refineries

- Signing sales contracts for reforming catalyst with Tehran Refinery and Pardis Petrochemical Phase III

2016

Production Infrastructure Development and Product Diversification

- Official inauguration of the co-precipitation catalyst production line with the presence of the Vice President for Science and Technology

- Signing sales contracts for methanation and high-temperature shift catalysts with Tabriz, Isfahan refineries and Razi Petrochemical

- Loading of DRI catalyst in Mobarakeh Steel's Module D

- Winner at the National "Iran-Made" Festival (presidential)

- Receiving the award for the best industrial company in the field of engineering and technology

- Sale of DRI catalyst for Saba Mega Module (Mobarakeh Steel)

- Organizing the Second Biennial Conference on Catalyst Localization and Direct Reduction Iron Process

- Loading of reforming catalyst in Razi Petrochemical's Ammonia Unit 3

2017

Production Leap and Localization of Advanced Technologies

- Localization of PERED technology catalyst

- Setting a new catalyst production record

- Catalyst loading in the largest steel mega module in the region (Kowsar Mega Module - Gol-e-Gohar Iron and Steel Development Co.)

- Localization of methanol synthesis catalyst

2018

Product Diversification and Market Leadership

- Loading of methane reforming catalyst at Zagros Petrochemical

- Loading at Shahid Kharrazi's Mega Module A (Mobarakeh Steel Complex)

- Localization of acetylene hydrogenation catalyst in partnership with Morvarid Petrochemical

- Ranking among the top 100 tech companies in the country

- Organizing the Third Biennial Conference on Catalyst Localization and Direct Reduction Iron Process

- Loading of PERED DRI catalyst at Baft Steel Complex

2019

Receiving Strategic Approvals and Production Records

- Obtaining approval for HTSC and LTSC catalysts from the Research Institute of Petroleum Industry

- Obtaining approval for Pre-Reforming catalysts from the Petrochemical Research and Technology Company

- First-ever production and loading of methanol synthesis catalyst in the country at Shiraz Petrochemical Complex

- First-ever production and loading of LTSC catalyst in the country at Shiraz Oil Refinery

- Signing sales contracts for catalysts for Masjed Soleyman Petrochemical and Isfahan Oil Refining Company projects

- Reaching a production record of 5 tons of catalyst per day

- Signing contracts for the sale of over 1000 tons of co-precipitation catalysts in 2019

- Loading of DRI catalyst at Khouzestan Steel's Unit 3, Saba Steel Complex (Mobarakeh), Jahan Foulad Sirjan, and Hormozgan Steel's Reformer A

2020

Completing the Technology Chain and Knowledge-Based Exports

- Loading of formaldehyde synthesis catalyst at Fars Chemical Industries Company (first time in the country)

- Contract for the production of acetylene hydrogenation catalyst with Morvarid Petrochemical (first time in the country)

- Loading the complete catalyst cycle at Masjed Soleyman Petrochemical

- First-ever export of Iranian Low-Temperature Shift Catalyst (LTSC) from the country

- Receiving the National Innovation Award for a product in the steel industry

- Signing MoUs with Apadana Petrochemical (methanol catalysts) and Hengam Petrochemical (urea and ammonia catalysts)

- Loading of HTSC catalyst at Kermanshah Petrochemical

2021

Export Leap, Production Infrastructure Development, and Expansion of Industrial Collaborations

In this year, SARV Oil & Gas Company succeeded in taking effective steps to enhance production capacity, develop export markets, and provide specialized services, while consolidating its position in the steel and petrochemical industries.

- Commissioning of Masjed Soleyman Petrochemical using Iranian catalysts, as the first example of full operation with a domestic chain

- Receiving the title of National Exemplary Exporter of the Year 2021 from relevant authorities

- Commissioning of a new catalyst production plant with a capacity of 5000 tons per year

- Loading of Direct Reduction Iron (DRI) catalysts in the country's steel complexes, including Kaveh South Steel, Arfa, Gol-e-Gohar, and Pars Foulad Sabzevar, as well as simultaneous loading of desulfurization (ZnO) and DRI catalysts at Mobarakeh Steel Complex in Isfahan

- Loading of ZnO, SMR, LTSC, and HTSC catalysts at Razi Petrochemical Complex, as one of the most comprehensive domestic localizations of the gas reforming and purification process in the country

- Signing a contract to supply DRI catalyst (inert, semi-active, active) with Mobarakeh Steel of Isfahan (Module A)

- Concluding a contract to supply catalyst with Pasargad Steel and Khouzestan Steel

- Supplying desulfurization guard (ZnO) for Khouzestan Steel

- Contract for industrial catalyst charging at Gol-e-Gohar Iron and Steel Development Complex (Gohar Mega Module)

2022

Foreign Market Development, Product Diversification, and Technological Exports

In 2022, SARV Oil & Gas Company took significant steps towards technological development and presence in international markets. This year marks a turning point in the company's history, accompanied by several key achievements:

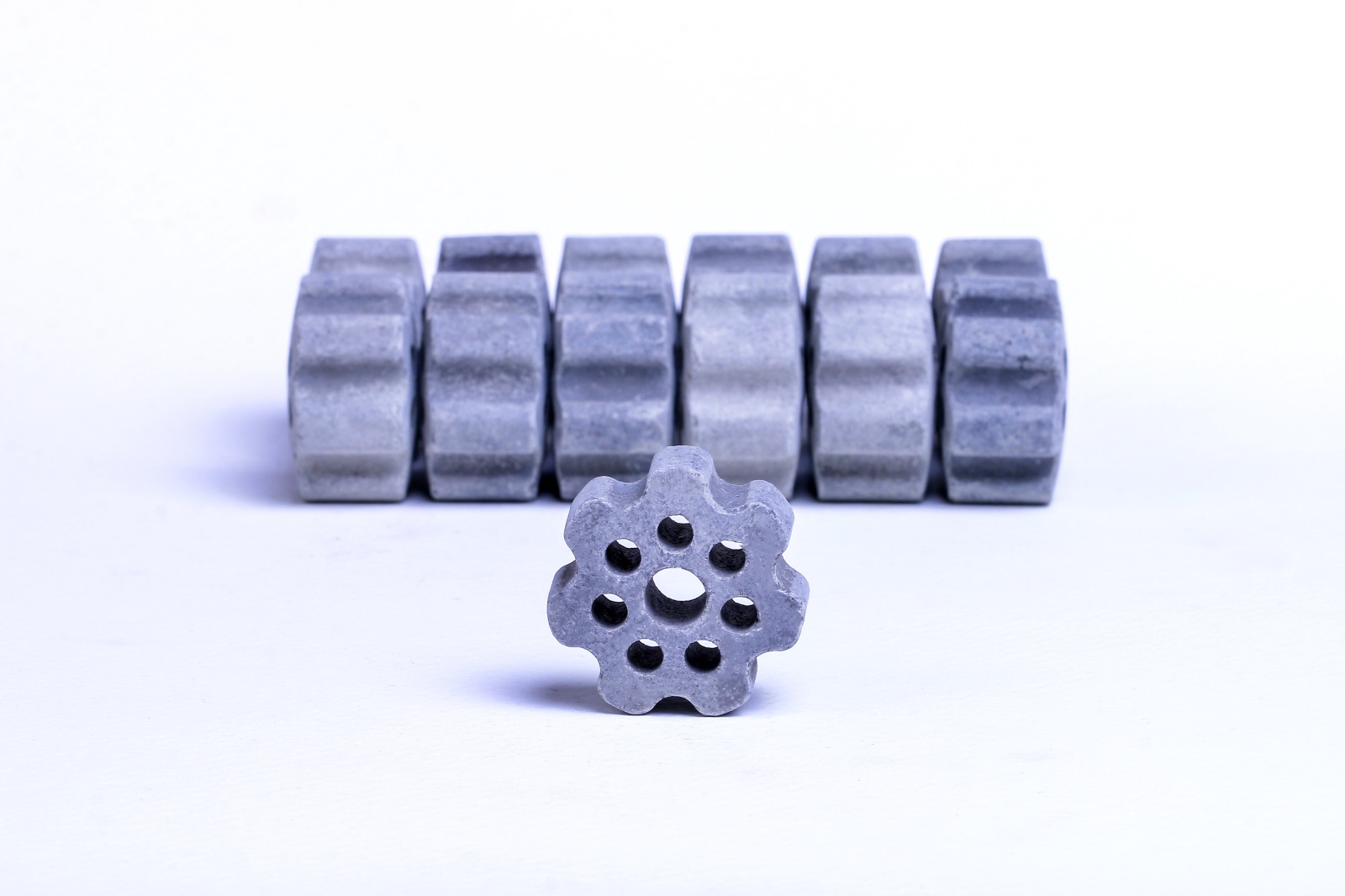

Unveiling of a new generation of improved catalysts with a Domed End design

- Increased efficiency and process productivity due to innovative design

- High resistance to abrasion, reduced pressure drop, and increased lifespan

- Domestic production and reduced dependency on imports

Technological and Export Successes at National and International Levels

- First official export of Iranian steel catalyst to international markets

- Production and operation of the first ethylene gas process catalyst at Morvarid Petrochemical

- Contract to supply DRI catalyst for Gol-e-Gohar's Tooba Mega Module (MMTE)

- Supplying desulfurization guard (ZnO) for the said project

- Contract to supply DRI catalyst for Kowsar Mega Module (Gol-e-Gohar Iron and Steel Development Co.)

- Contract to supply Low-Temperature Shift Catalyst (LTSC - SARV-140) and High-Temperature Shift Catalyst (HTSC - SARV-150) with Mobarakeh Steel of Isfahan

- Export of DRI catalyst to Russia

- Contract to supply PERED catalyst (inert, semi-active, active) with Miyaneh Steel Complex

- Sales contract for DRI catalyst with Sirjan Iranian Steel and Jahan Foulad Sirjan

- Supplying desulfurization guard (ZnO) with Plant Construction Kish Company

2023

Expanding Collaboration with EPC Projects and Commissioning Complexes

In 2023, SARV Company, focusing on modern steel projects and EPC-driven needs, signed numerous contracts to supply catalysts for ongoing projects.

- Contract to supply DRI catalyst with MMTE for the revival project of Jahan Foulad Sirjan's unit 2

- Signing a contract to supply catalyst with Ghadir Neyriz Steel Complex and Sepiddasht Steel Complex

- Supplying desulfurization guard (ZnO) for Mobarakeh Steel of Isfahan and projects managed by MMTE

2024

Consolidating Key Role in Supply Chain and Entering New National Projects

In 2024, SARV Company further solidified its position in the DRI catalyst supply chain by expanding its customer base and participating in mega-module projects, as well as with emerging and independent industrial companies.

- Signing a contract to supply PERED catalyst with Setareh Simin Hormoz Company (MME)

- Signing a contract to supply DRI catalyst for the Gohar Zamin Mega Module project (FSTCO)

- Signing a contract to supply DRI catalyst and desulfurization guard (ZnO) with Module C of Kaveh South Kish Complex

- Signing a contract to supply catalyst with Ardakan Yazd Steel Complex, Ghadir Iranian Steel, and Mobarakeh Steel of Isfahan

- Signing a contract to supply DRI catalyst with Saba Steel and Rolling Company of Isfahan

- Signing a contract to supply desulfurization guard catalyst (ZnO) for Pasargad Steel

- Signing a contract to supply DRI catalyst with Saba Foulad Khalij Fars

2004-11-29

SARV Company Established

SARV Oil & Gas Industries Development Company was officially founded with a strategic focus on acquiring advanced Gas-to-Liquids (GTL) technology and developing industrial catalyst manufacturing capabilities.

- Official launch of SARV Oil & Gas Industries Development Company.

- Strategic goal-setting for localizing GTL technology and developing the technical expertise for advanced catalyst production.

Initiating Catalyst Technology Industrialization

Launched the industrial-scale development of steam reforming catalysts.

Entry into Steel Industry Catalysts

Began the industrialization phase for producing Direct Reduction Iron (DRI) catalysts.

Technical Advancement and Field Testing

- Registered patents for proprietary catalyst technologies.

- Commenced semi-industrial loading of DRI catalysts at Khouzestan Steel Company.

First Industrial Use of Indigenous Catalysts

Achieved the first-ever industrial deployment of a domestically-produced methane reforming catalyst in Iran at the Shiraz Petrochemical Complex.

National Recognition for Innovation

- The GTL project was recognized as a top technology project at the prestigious Khwarizmi International Award festival.

- Initiated semi-industrial testing of DRI catalysts at Mobarakeh Steel Company.

Commencement of Mass Production of Nickel Catalysts

Officially launched the industrial production line for nickel-based catalysts.

A Major Step in GTL Commercialization

Commissioned Iran's first semi-industrial Gas-to-Liquids (GTL) unit, with a capacity of 1 barrel per day.

Expansion of Catalyst Product Portfolio

- Launched production of enhanced steam reforming catalysts.

- Received the joint "Top Product of the Year" award with Khouzestan Steel Company.

Operational Entry into Petrochemical and Steel Industries

- Completed the first industrial loading of DRI catalyst at Module B of Mobarakeh Steel.

- Loaded reforming catalysts at Fanavaran, Razi, and Shiraz Methanol Petrochemical Plants.

- Obtained technical approval from the Research Institute of Petroleum Industry (RIPI) for the industrial reforming catalyst production line.

Gaining Knowledge-Based Status & Initiating Technical Outreach

- Officially registered as a knowledge-based manufacturing company by the Vice-Presidency for Science & Technology.

- Loaded steam reforming catalyst at Pardis Petrochemical Complex.

- Organized the First National Conference on Catalyst and DRI Process Localization.

Market Expansion and Production Records

- Achieved the first-ever loading of a secondary reforming catalyst in Iran (at Razi Petrochemical).

- Reached a cumulative production milestone of 1 million liters of various catalysts.

- Deployed DRI catalysts at Khouzestan Steel (Unit 3), Mobarakeh (Module A), and Hormozgan Steel.

- Loaded methane reforming catalyst at Arak and Shiraz Refineries.

- Signed sales contracts with Tehran Refinery and Pardis Petrochemical Phase III.

Infrastructure Development and Product Diversification

- Officially opened the co-precipitation catalyst production line, attended by the Vice President for Science & Technology.

- Signed sales agreements for methanation and HTSC catalysts with Tabriz and Isfahan Refineries, and Razi Petrochemical.

- Loaded DRI catalyst at Module D of Mobarakeh Steel.

- Recognized as a winner at the "Iran-Made" National Festival.

- Awarded Best Industrial Company in Engineering & Technology.

- Secured a DRI catalyst contract for the Saba Mega Module (Mobarakeh Steel).

- Organized the Second Biannual Conference on Catalyst & DRI Process Localization.

- Loaded reforming catalyst at Razi Petrochemical's Ammonia Unit 3.

Breakthrough in Production and Advanced Technology Localization

- Successfully localized the PERED process catalyst technology.

- Set a new company record for catalyst production volume.

- Loaded catalysts at the region's largest steel mega module (Kowsar Mega Module - Gohar Dasht Steel).

- Achieved localization of methanol synthesis catalyst technology.

Product Diversification and Market Leadership

- Loaded methane reforming catalyst at Zagros Petrochemical.

- Completed loading at Mega Module A of the Shahid Kharrazi Complex (Mobarakeh Steel).

- Localized acetylene hydrogenation catalyst in collaboration with Morvarid Petrochemical.

- Ranked among Iran's Top 100 Technology Companies.

- Held the Third Biannual Conference on Catalyst & DRI Process Localization.

- Loaded PERED DRI catalyst at Baft Steel Complex.

Receiving Strategic Certifications and Setting Production Records

- Obtained HTSC and LTSC catalyst approval from the Research Institute of Petroleum Industry (RIPI).

- Received pre-reforming catalyst approval from the NPC Research & Technology Company.

- Achieved the first-ever production and loading of methanol catalyst at Shiraz Petrochemical.

- Completed the first-ever production and loading of LTSC catalyst at Shiraz Oil Refinery.

- Signed catalyst supply contracts for the Masjed Soleyman Petrochemical and Esfahan Oil Refining Company projects.

- Reached a daily production milestone of 5 tons of catalyst.

- Sold over 1,000 tons of co-precipitation catalysts during the year.

- Deployed DRI catalysts at Khouzestan Steel (Unit 3), Saba Steel, Sirjan Jahan Steel, and Hormozgan Steel (Reformer A).

Completing the Technology Chain and Launching Knowledge-Based Exports

- Completed the first-ever formaldehyde catalyst deployment at Fars Chemical Industries Company.

- Secured a contract for acetylene hydrogenation catalyst with Morvarid Petrochemical (a first in Iran).

- Loaded a complete catalyst cycle at Masjed Soleyman Petrochemical.

- Achieved the first-ever export of Iranian-made LTSC catalyst.

- Won the National Innovation Award for a Steel Industry Product.

- Signed MOUs with Apadana Petrochemical (methanol catalysts) and Hengam Petrochemical (urea and ammonia catalysts).

- Loaded HTSC catalyst at Kermanshah Petrochemical.

Export Expansion, Infrastructure Growth, and Industrial Integration

During this year, SARV not only solidified its position in the steel and petrochemical industries but also took significant strides in enhancing production capacity, developing export markets, and delivering specialized services.

- Commissioned the Masjed Soleyman Petrochemical plant using a full chain of locally-manufactured catalysts—a landmark achievement in domestic technology integration.

- Recognized as the National Exemplary Exporter of the Year for 2021.

- Commissioned a new catalyst production facility with an annual capacity of 5,000 tons.

- Deployed Direct Reduction Iron (DRI) catalysts at major national steel complexes including Kaveh South, Arfa, Gohar, and Pars Sabzevar Steel, and performed a simultaneous loading of ZnO and DRI catalysts at Mobarakeh Steel Complex.

- Deployed a full suite of ZnO, SMR, LTSC, and HTSC catalysts at Razi Petrochemical, marking a milestone in localizing gas reforming and purification solutions.

- Signed a supply contract for a full range of DRI catalysts (inert, semi-active, active) with Mobarakeh Steel (Module A).

- Finalized supply agreements with Pasargad Steel and Khouzestan Steel.

- Supplied ZnO sulfur guard for Khouzestan Steel.

- Contracted for industrial catalyst charging at the Gohar Dasht Steel mega module.

International Market Penetration and Technological Exports

In 2022, SARV took significant steps in technological development and international market entry, marking a turning point with several key achievements:

Unveiled a new generation of high-performance catalysts featuring an advanced domed-end design.

- Enhanced process efficiency and productivity through innovative design.

- Superior abrasion resistance, reduced pressure drop, and extended operational lifespan.

- Fully indigenous manufacturing, reducing import dependency.

Key National and International Milestones:

- Achieved the first official export of Iranian-made DRI catalysts to international markets.

- Completed the first deployment of an Ethylene Oxide (EO) catalyst at Morvarid Petrochemical.

- Secured a DRI catalyst contract for the Tooba Mega Module (Golgohar - MMTE).

- Supplied ZnO sulfur guard for the same project.

- Contracted to supply DRI catalyst for the Kowsar Mega Module (Golgohar Steel Development Co.).

- Finalized HTSC & LTSC catalyst contracts with Mobarakeh Steel.

- Exported DRI catalyst to Russia.

- Secured a PERED catalyst supply contract with Miyaneh Steel Complex.

- Completed DRI catalyst sales to Sirjan Iranian Steel and Jahan Foulad Sirjan.

- Signed a ZnO guard contract with Plant Construction Kish.

Expanding Collaboration with EPC Projects and Emerging Plants

In 2023, with a focus on new steel projects and EPC-driven requirements, SARV secured multiple contracts to supply catalysts for new and ongoing industrial developments.

- Signed a DRI catalyst supply contract with MMTE for the Sirjan Jahan Steel Project (Module 2).

- Finalized catalyst supply contracts with Ghadir Neyriz and Sepiddasht Steel Complexes.

- Supplied ZnO sulfur guard for Mobarakeh Steel and other MMTE-managed projects.

Securing a Key Role in the Supply Chain and Engaging in New National Projects

In 2024, by expanding its client base and participating in mega-module projects, as well as with emerging and independent industrial companies, SARV further solidified its position in the direct reduction catalyst supply chain.

- Signed a PERED catalyst supply contract with Setareh Simin Hormoz (MME).

- Secured a DRI catalyst contract for the Goharzamin Mega Module project (FSTCO).

- Finalized a contract for DRI and ZnO catalysts with Kaveh South Steel Complex (Module C).

- Signed catalyst supply agreements with Ardakan Yazd Steel, Ghadir Iranian Steel, and Mobarakeh Steel.

- Agreed to supply DRI catalyst to Saba Esfahan Steel and Rolling Complex.

- Contracted to supply ZnO guard catalyst for Pasargad Steel.

- Signed a DRI catalyst supply contract with Saba Foolad Persian Gulf.

```